After setting foot on the Moon, the next destination for humankind is Mars, which presents a whole new set of challenges in speedy, long-distance space travel.

In a major step for moving heavy loads across the Solar System in short time, NASA just announced another successful test of an innovative rocket engine with enough thrust to get us to the Red Planet.

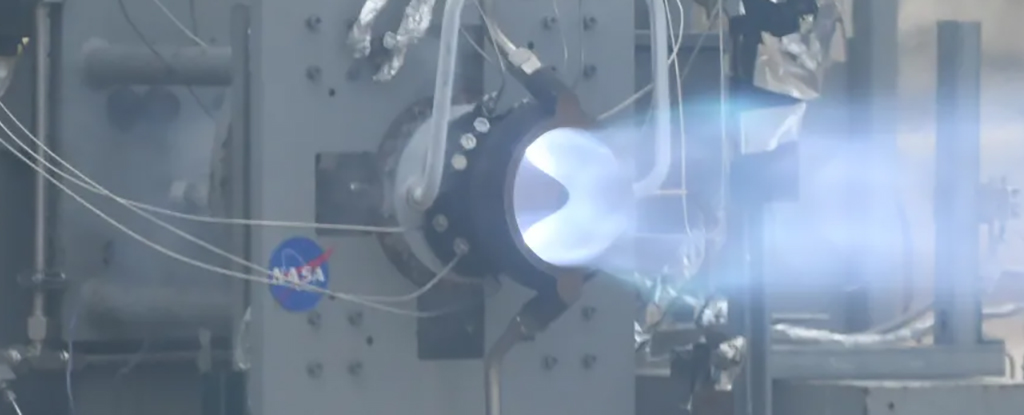

Putting the prototype Rotating Detonation Rocket Engine (RDRE) through its paces at the NASA Marshall Space Flight Center in Alabama has set new records for the technology, achieving 25,810 newtons (5,800 pounds) of thrust for 251 seconds.

That beats the 17,800 newtons of thrust managed for nearly a minute that the rocket engine managed in 2022, with the results validated early in 2023.

Eventually, the aim is to build a fully reusable 44 kilonewton class RDRE to improve on traditional liquid rocket engines.

“The RDRE enables a huge leap in design efficiency,” says combustion devices engineer Thomas Teasley, who is leading the RDRE project at the Marshall Space Flight Center.

What makes the RDRE so revolutionary is that it makes use of a sustained detonation circling around a ring-shaped channel, fed by a mix of fuel and oxygen which is ignited by each passing explosion.

The technology has been in development for years, and in lab-based testing since 2020, but it’s only now that scientists are showing that it’s stable and manageable enough to be used in actual rockets to take us to space.

frameborder=”0″ allow=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share” allowfullscreen>

Crucially, the RDRE uses less propellant fuel than conventional rocket engines, and is simpler in terms of its machinery and mechanisms. That means going into space becomes cheaper, and traveling further distances becomes possible.

We know that it costs a lot to explore space (perhaps part of the reason why we haven’t had any alien visitors yet) and this would represent a substantial upgrade in terms of how much fuel would be needed to get across long distances.

Also of note is that NASA has used 3D printing techniques to produce bespoke machine parts that are strong enough to withstand the extreme heat and pressure involved in the RDRE design.

The engineers behind the test say that they now have a better understanding of how the combustor could be scaled and adapted to support different levels of thrust, different types of engine system, and different classes of mission.

NASA is hoping that the first people might set foot on Martian soil sometime in the 2030s. There are still plenty of hurdles to overcome in terms of getting to Mars and surviving once we’re there, but having an efficient means of propulsion helps solve on of the more significant obstacles.

“It demonstrates we are closer to making lightweight propulsion systems that will allow us to send more mass and payload further into deep space, a critical component to NASA’s Moon to Mars vision,” says Teasley.