In a serendipitous discovery, researchers have created a new class of materials called ‘glassy gels’ that are half liquid but hard to break.

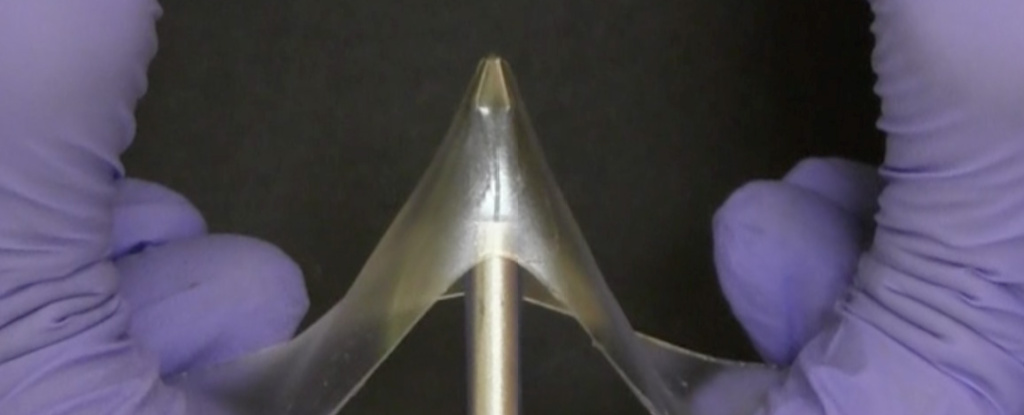

Stretchy, strangely adhesive, and able to ‘self-heal’ if cut, the surprising properties of these gels potentially make them useful for a wider range of applications than commonly-used plastics, which are either hard and brittle or soft and easily torn.

“We’ve created a class of materials that we’ve termed glassy gels, which are as hard as glassy polymers, but – if you apply enough force – can stretch up to five times their original length, rather than breaking,” says Michael Dickey, materials scientist at North Carolina State University (NCSU).

But as with so many fortuitous scientific discoveries, the goal was never to make a whole new class of subtances, Dickey tells ScienceAlert.

“We stumbled into these interesting materials,” he says, when NCSU researcher Meixiang Wang was experimenting with ionogels, materials made of a polymer swollen with an ionic liquid that conducts electricity.

Wang was trying to make stretchable, wearable devices that might be used in a pressure sensor, other medical devices or robotics. Altering the composition, Wang produced a gel that looked at first like a “mundane piece of transparent, flexible plastic” before testing showed it was very hard – but not brittle like other common plastics.

“Once we realized they have remarkable properties, we dove in to understand them better,” Dickey says.

The glassy gels are made using an ionic liquid, which is similar to water but made entirely of charged particles, allowing it to conduct electricity. When mixed with a polymer precursor the liquid pushes the polymer chains apart, making the material soft and stretchy. At the same time, the ions are also strongly attracted to the polymer chains, preventing them from separating.

“The end result is that the material is hard due to the attractive forces, but is still capable of stretching due to the extra spacing,” explains Dickey.

frameborder=”0″ allow=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share” referrerpolicy=”strict-origin-when-cross-origin” allowfullscreen>

The glassy gels don’t dry out, even though they consist of between 50 to 60 percent liquid, and testing showed they have “enormous” fracture strength and toughness.

The material can also ‘self-heal’, reforming if cut, and has a kind of memory that allows a stretched gel to hold its shape, only to contract to its original form when heated.

Though unusual, such regenerative properties aren’t particularly new, especially in stretchy gel-like materials. Recently, scientists have succeeded at the much harder task of making typically rigid materials, such as metals, glass, solar panels and concrete that heal when cracked. If commercialized, materials like these, capable of repairing themselves when damaged, could help to reduce waste, in the construction, electronics, and fashion industries.

But the odd combination of the glassy gels’ remarkable nature is something researchers want to explore further.

“Maybe the most intriguing characteristic of the glassy gels is how adhesive they are,” Dickey says. “We understand what makes them hard and stretchable, [but] we can only speculate about what makes them so sticky.”

More testing and optimization of the ‘gel’ is obviously required before these gels can be used in any practical way, but thinking about potential applications, Dickey says tough materials that conduct electricity (like the gel does) are useful in batteries.

Other potential uses include 3D printing plastic-like materials using simpler techniques than melt-processing – the method currently used to produce commercial plastics from starter resins. This process often involves shipping products to multiple facilities for each step of plastic production, whereas the glassy gels can be injected into a mold and cured with UV light.

But before working towards applications, Dickey says his team wants to better understand the basics of how these materials form, and why there seems to be a ‘magic ratio’ of solvent to polymer that creates the gels’ unique properties.

“Considering the number of unique properties they possess, we’re optimistic that these materials will be useful,” Wang says.

The study has been published in Nature.